Watertight fastening systems

The installation of superstructures such as, for example, photovoltaic panels, solar thermal, pipes, heating cables, satellite dishes, etc., have always raised concerns and posed particular limitations to both the designer and the applicator.

The experience accumulated over more than 30 years in the waterproofing industry has enabled the development of a series of products, identified under the brand name FastEnerGrip, in able to guarantee at the same time ana high resistance mechanics and a total and perfect watertightness.

The production technology and in-line control stages allow products with a constant quality standard to be brought to market. At the customer's explicit request, the FastEnerGrip system can be realised using specific PVC membranes; FPO/TPO, EPDM, BPP/BPE.

Despite its young constitution of societythe project FastEnerGrip has a history of more than 10 years having been tested on various construction sites with different environmental conditions. This has resulted in all-round insurance cover, which testifies to the validity of the solution.

FOREWORD

The fastening of superstructures on building roofs represents a major challenge in both civil and industrial construction.

The designer is faced with the following issues, in view of the fact that he is obliged to comply with the Ministerial Decree of 17 January 2018 - update of the Technical Standards for Construction Chapter 7.2.4:

- ensure a solid and secure fastening that is able to withstand all the stresses that the weathering agents through the superstructure place on the fasteners in terms of both tensile and shear strength;

- ensure perfect waterproofing through the chosen fixing system.

Proroof Ltd. is constantly striving, through studies and applications, to offer the FastEnerGrip system to the designer, applicator and client.

The FastEnerGrip system solves all the problems required for a secure, durable and waterproof fastening.

Thanks to the patented FSTENERGRIP system, Proroof is able to offer the following advantages :

- Tensile strengths from 3.5 kN up to 54 kN;

- Shear strengths from 6.9 kN up to 35 kN;

- Absolute tightness of the fastening system;

- Suitable for use on surfaces with an inclination of more than 45°.

- Constant over time and reproducible characteristics.

The FastEnerGrip system is assembled entirely in the factory under constant environmental conditions and in the absence of pollutants

such as: dust water etc. elements that can affect mechanical performance.

FASTENERGRIP

FastEnerGrip is a system designed to ensure the fastening of equipment such as photovoltaic systems, solar thermal systems, parapets, lifelines, air treatment systems and other equipment that is generally positioned on roofs waterproofed with visible coverings such as: FPO / TPO, PVC, EPDM, bituminous membranes, liquid waterproofing etc.

FastEnerGrip's special simultaneous dual induction assembly technology guarantees a secure connection

excellent mechanical performance directly to the roof structure without through-fixing elements.

Once installed and welded by thermo-fusion if installed correctly FastEnerGrip eliminates the rack-and-pinion movement and guarantees uncompromising watertightness.

The design of the FastEnerGrip was conceived to make it easy to install for those in the industry.

Every single batch of FastEnerGrip® is subjected to systematic controls that are carried out both at in-house laboratories and at certified external facilities.

A sophisticated thermographic control system, mounted in-line, allows any defects to be detected immediately.

In addition, our laboratories are equipped to perform both shear and tensile strength tests.

These tests can also be carried out, at the customer's specific written request, at certified external laboratories or on site. In addition to systematically checking the finished product, Proroof srl constantly tests the membranes used in the production of the FastEnerGrip® system.

At the customer's request, tests are also carried out on previously installed membranes subject to the FastEnerGrip® system placement

The FastEnerGrip system consists of:

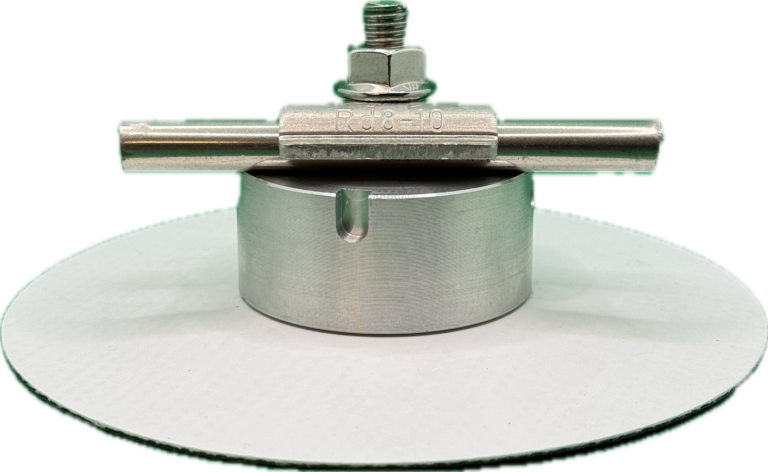

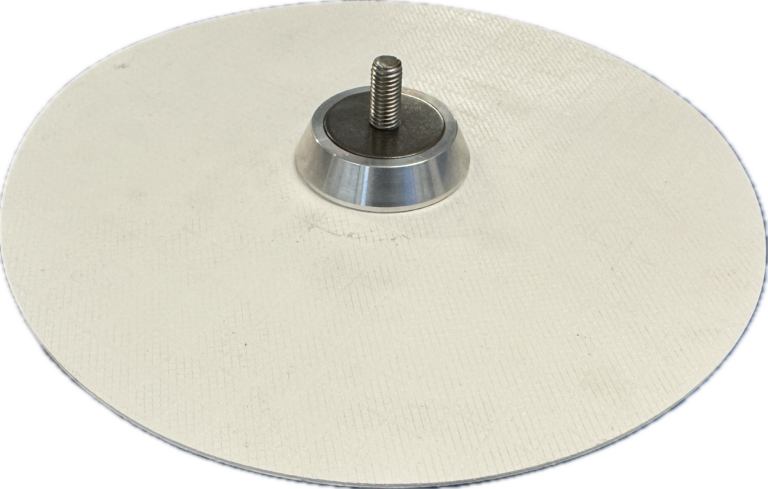

- 90 m disc, made of Anticorodal aluminium, 10 mm thick, which provides a perfect support for the structures and/or frames on which the superstructures will be installed.

- Clamping bolt M10x35 A2, bolts M12 x 35 A2 can be supplied at the customer's request.

- FastEnerGrip can be produced using all types of waterproofing membranes on the market and are fully compatible with laying systems using mechanical fixing, bonding or ballasting.

- The FastEnerGrip system can be used on all types of substrates and thicknesses:

Metal > than 0.4 mm

Wood > 10 mm

Concrete > 40 mm

Cement slabs > 10 mm

The possibility of implementing the FastEnerGrip system with any waterproofing membrane on the market ensures that the 100% is compatible with the waterproofing system installed and/or to be installed.

The FastEnerGrip system does not require preparation prior to the application of the waterproofing membrane for its positioning on the structure, which helps save time and labour with the possibility of changing the laying layout up to the last moment.

The correctly installed FastEnerGrip ensures a secure and powerful attachment of the equipment to the roof, guaranteeing total watertightness.

- Simple installation process that saves time and labour.

- 100% compatible with all waterproof membranes prepared for induction thermofusion.

- It helps to protect the roof covering from damage due to the rack movement caused by the ballast and from seepage due to the use of sealants for through mechanical fasteners.

- Large, 250 mm diameter flange to be welded to the main waterproofing membrane.

VERSIONS

The FastEnerGrip system is available in the following versions:

FastEnerGrip PV- base

For use when the required mechanical performance does not exceed 3.0 kN tensile and 2.0 kN shear

FastEnerGrip PV- P- 0.6

To be used when the required mechanical performance does not exceed 9.5 kN tensile and 6.8 kN shear

FastEnerGrip PV- HP

To be used when the required mechanical performance does not exceed 28.0 kN tensile and 20.0 kN shear

FastEnerGrip HP-LV

To be used when the required mechanical performance does not exceed 44.0 kN tensile and 32.0 kN shear (System used for positioning Life Line components.

The system is realised with M16x 30/40/50/60/70/100 bolts

A wide range of accessories allows photovoltaic panels to be positioned from coplanar to the roof up to vertical inclinations.